Product recalls can be a big deal for your business. If you’re in the slipper business, you want your slippers to be the best quality, safe and comfortable. In this article, I’ll show you how to do it step-by-step. I’ll also give you some things to think about so you can minimize the damage to your business and keep your customers happy.

1. Nature of Product Recalls

The slipper industry, like any other footwear industry, can have product recalls for a variety of reasons. Here are some of the reasons why you might have a product recall in the slipper industry:

- Material Defects: Poor-quality materials can cause your slippers to wear out too fast, break, or even cause health problems like allergic reactions..

- Manufacturing Errors: You didn’t stitch them right, the soles are weak, or you didn’t test them properly for safety.

- Safety Issues: Your non-slip claims don’t hold up. You use chemicals that are over the safety limits. You don’t have enough fire resistance.

- Labeling and Compliance Failures: You didn’t meet the regulatory requirements. You mislabeled the materials. You didn’t have the right safety certifications.

Knowing what can go wrong will help you avoid problems or fix them quickly if they happen.

2. Prepare a Robust Recall Management Plan

Before you ever have a recall, you need to have a plan. Here are some things you’ll want to have in your plan.

- Identification of Key Stakeholders:You need a team to handle a recall. You should have a legal person, a logistics person, a customer service person, and a marketing person. Assign roles to each person. Make it clear who is going to handle communication, logistics, and customer relations.

- Supplier Communication Channels: Establish regular communication with your suppliers about product quality, compliance, and traceability. The faster your suppliers can respond, the faster you can get your recall done..

- Recall Notification Systems:Establish an internal system to monitor your product quality and customer complaints. The faster you recognize you have a potential recall situation, the faster you can react.

Your recall management plan should be clear, concise, and tested periodically to make sure it works.

3. Regulatory Requirements and Compliance

As a buyer, you need to know the local and international regulations that govern the production and sale of slippers. In the European Union (EU), slippers must comply with the following regulations:

- General Product Safety Directive (GPSD): This directive says that products sold in the EU must be safe for consumers to use. If your slipper product is not safe for consumers to use, you may need to recall it.

- Chemical Safety Standards (REACH):Slippers made from leather, rubber, or synthetic materials must meet chemical safety standards. These standards limit harmful substances like lead, cadmium, and formaldehyde.

- Textile Labeling Requirements: Slippers made from fabric must comply with EU textile labeling regulations. These regulations require that all materials used in the production of slippers are labeled correctly.

In Germany, the Product Safety Act (ProdSG) is the law that governs the safety of consumer goods. You need to make sure your suppliers comply with this law.

4. Identifying Product Recall Triggers

To avoid a recall, catch problems early. Here are a few ways to identify potential triggers:

- Customer Complaints:If you start getting a lot of complaints about the quality, durability, or safety of your slipper product, you might have a problem.

- Quality Control Audits: Regular audits of your production facilities by your suppliers and independent auditors can catch issues before your products hit the market.

- Supplier Testing and Certification: Make sure your suppliers are providing you with regular testing and certification of their materials and products. Look for independent third-party testing results, especially for safety features like non-slip soles or hypoallergenic materials.

By having a system in place to monitor and address these triggers early, you can avoid having to do a big recall.

5. Steps to Take During a Product Recall

When you have to do a recall, how fast and how well you do it can make a big difference in your brand and customer loyalty. Here are the key steps to manage your recall effectively:

a. Notification and Communication

- Internal Communication: As soon as you know you have a problem, tell everybody in your company who needs to know. This includes your customer service people, your sales team, your logistics people, and your upper management.

- Supplier Notification: Contact your supplier immediately to find out what’s wrong. Work with them to recall the bad batch from their end.

- Regulatory Authorities: Tell the local authorities about your recall. In Germany, you would tell the Federal Institute for Occupational Safety and Health (BAuA). In the EU, you would tell the relevant EU agencies. You need to do this to stay compliant with local regulations.

- Customer Communication: Tell your customers about your recall. You can do this with in-store notices, online alerts, and emails to your registered customers. Tell them how to return or dispose of your product.

b. Product Removal from Shelves and Inventory

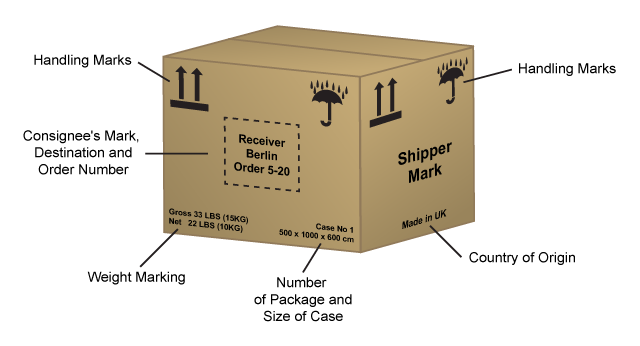

- Logistics Coordination: Get your warehouse and retail partners to take your product off the shelves and out of their online stores. Make sure they separate your recalled product from your other inventory so they don’t accidentally sell it.

- Reverse Logistics Setup: Get your customers to send your product back to you. Tell them how to do it. Depending on how bad your recall is, you may need to pay for return shipping or give them a store credit.

c. Compensation or Replacement Offers

- Refund or Exchange Options: Give your customers their money back or replace your product. Depending on how bad your recall is, you may need to give them their money back or replace your product. A recall done right can turn a negative experience into a positive one by showing your customers you care about their safety and satisfaction.

- Customer Support Team: Give your customer service people the information they need to handle customer questions, complaints, or concerns. Make sure they all give the same answers.

6. Post-Recall Evaluation and Preventive Measures

After you’re done with your recall, evaluate what happened and put things in place to keep it from happening again. Here’s what you need to do:

a. Supplier Evaluation and Audits

- Root Cause Analysis: Work with your supplier to figure out what went wrong. Was it a material defect, a manufacturing error, or a failure in quality control?

- Supplier Audits: Consider doing more audits of your suppliers, especially if a supplier caused the defect. Put in place better quality control and testing moving forward.

- Contract Revisions: Revise your supplier agreements to include stricter penalties for noncompliance or defective products. Make sure your suppliers are legally obligated to share the burden of recall costs if they caused the problem.

b. Internal Process Improvement

- Review of Quality Assurance Procedures: Evaluate whether your quality assurance processes caught the defect early. You may need to update your inspection protocols, testing thresholds, or how often you audit the product.

- Customer Feedback Integration: Incorporate customer feedback into your post-recall strategy. Listen to your customers about what went wrong so you can avoid it in the future.

c. Public Relations and Brand Reputation Management

A product recall can hurt your brand’s reputation. To minimize the damage and maybe even turn the recall into an opportunity to build trust:

- Transparency:Be transparent about what happened, why you had to recall the product, and what you’re doing to make sure it doesn’t happen again.

- Media and Public Relations Strategy: Develop a PR strategy to handle the media and public perception of the recall. Admitting the problem and showing how you’re fixing it can help you keep your customers.

- Re-engagement Campaigns: After you’ve fixed the recall, consider running customer re-engagement campaigns to win back their trust. Offer discounts, loyalty programs, or exclusive offers to make up for the inconvenience.

7. Leveraging Technology for Recall Management

In today’s digital world, technology can help you manage your product recalls more efficiently.

- Inventory Management Software: Use advanced inventory management systems that track products from your suppliers to your shelves. This way, you can find and isolate the defective batches faster during a recall.

- Customer Feedback Tools: Implement online tools or mobile apps that allow your customers to easily report defects or issues with your slipper products. Real-time feedback can help you catch problems early and avoid a big recall.

- Automated Recall Notifications: Use automation tools to send recall notices through multiple channels like email, SMS, and in-app notifications. Automating this process will help you communicate faster and make sure all the people who bought your product know about the recall.

Conclusion

When it comes to handling product recalls in the slipper industry, you need to be proactive, communicate well, and follow the rules. As a buyer, you need to make sure your products are high quality and safe before they go to market. But when you do have a recall, handle it quickly and efficiently to minimize the damage and maybe even build trust.

By preparing in advance, working closely with your suppliers, and evaluating what happened after the recall, you can make sure you handle recalls in a way that protects your business and your customers.