Foreward: managing costs in large-scale slipper orders is a critical task for a buyer. In B2B transactions, where margins are tight, even small inefficiencies can have significant financial impacts. This is particularly relevant when ordering products like slippers, which may have high competition and relatively low unit prices. Therefore, it is essential to have an effective cost-management strategy to maintain profitability while ensuring the quality and timely delivery of your products.

This article will cover key cost management strategies when ordering slippers in bulk, including negotiating pricing, managing supply chain logistics, optimizing inventory, and maintaining quality control. By following these strategies, you can streamline your purchasing operations, minimize waste, and improve profitability.

1. Understand the Cost Components

To manage costs effectively, it’s important to first understand the different components that make up the total cost of slipper orders. These include:

- Unit Price: The base cost per pair of slippers from the manufacturer.

- Shipping and Logistics: Freight charges for transporting slippers from the factory to your location.

- Duties and Taxes: Import duties, VAT, or any other applicable taxes.

- Storage Costs: Warehousing or storage fees, especially if you are managing large inventory levels.

- Packaging Costs: Don’t forget the cost of packing materials or even putting labels on the slippers.

- Quality Control: The cost of inspections or product testing to ensure the slippers meet your quality standards.

By breaking down these elements, you can pinpoint which areas offer the most potential for cost savings.

2. Negotiate Pricing with Suppliers

a. Bulk Discounts

One of the most obvious ways to manage costs in large-scale slipper orders is through bulk purchasing. Most manufacturers will offer discounts based on volume. As a buyer, it’s important to leverage your purchasing power to negotiate favorable terms.

- How to approach bulk discounts: Start by comparing prices from different suppliers to get a feel for

what the going market rate is. Then, you can provide some reassurance to the supplier that you’re in it for a long-term relationship, promising to place regular or recurring orders.

b. Payment Terms

You can also negotiate payment terms. Paying upfront or early gives the supplier cash. If you need extended terms, ask for them. Some suppliers will give you more time to pay, sometimes even months more than standard terms, just to get your business.

- Example terms: Also, you can negotiate payment terms. If you can push out those payment

terms from 30 days to 60 or even 90 days, it’s like you have 90 days to sell a part of that inventory before you have to pay for it.

c. Supplier Competition

When you make an order, make sure you get multiple suppliers to quote on slippers. Let each one know you’re shopping around. This puts them in a position where they are competing with each other.

- Benchmarking tip: Use data from past orders or industry standards to benchmark prices when negotiating.

3. Optimize Shipping and Logistics Costs

a. Select the Right Shipping Method

Shipping is another expense to consider in your purchase price. How fast do you need it? Where is it coming from? Where is it going to? Do you need to have it shipped by sea, air, or ground?

- Cost comparison: For example, air freight might be 3-4 times more expensive than sea freight but could save time in high-demand situations.

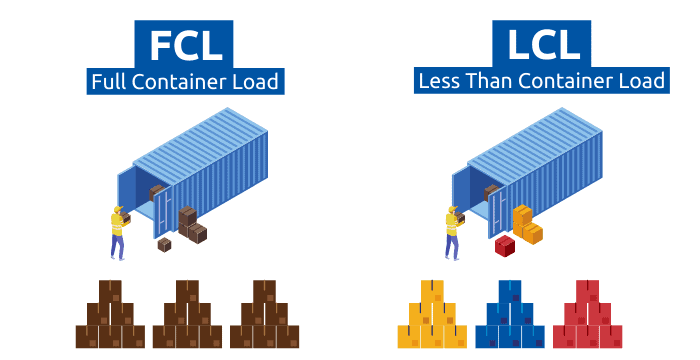

- Consider Full Container Loads (FCL): Opting for FCL shipments can reduce costs as compared to Less than Container Loads (LCL), where you share container space with other businesses.

b. Consolidate Shipments

Combine multiple small-buy orders into one large shipment. Many logistics companies offer reduced rates for larger volume shipments.

c. Inland Transportation

When the slippers get to the port or airport, you have to get them to your warehouse or distribution center. When they’re moving from the port to your place, that costs money, too.

d. Customs and Duties Optimization

Makes sure you know what the duty and taxes for slippers are since your slippers will have different tariff codes depending on the material used (e.g. leather, textile, rubber). These codes determine the appropriate duty. Don’t get surprised by this and make sure you happen to know what they are! While you’re at it, go read “Incoterms” and always negotiate anything with your suppliers. For slippers, typically you need to say that your supplier ships them “DDP” (Delivered Duty Paid).

- Tax optimization:Sometimes, you can replace one material or component with another one that has a lower duty rate, which saves on costs.

4. Inventory Management

a. Just-in-Time (JIT) Inventory

Just-in-time inventory management allows you to minimize storage costs by receiving goods only when they are needed. While this can be riskier in case of supply chain disruptions, it can significantly reduce warehousing expenses for large-scale slipper orders.

b. Safety Stock

Having a specific level of safety stock is good because if you don’t, you’re going to stockout and lose sales. However, if you have way too much, then you’re depleting your cash reserves and increasing your

storage costs. That’s why looking at sales trends and supplier lead time performance is important. That’s the whole reason for safety stock so you don’t have overstocked items.

c. Forecasting Demand

You’ve got to be able to forecast demand so you don’t over order or under order. Sales data, market trends, and seasonality can all help you forecast demand better for slippers. Often your inventory management system will do this for you if you have such a thing. It tracks your dogs booties sales each of the last three years, looks at trends, makes sure you’re predicting future sales and not overstocking.

- Forecasting tools: Use systems like ERP (Enterprise Resource Planning) or demand forecasting software to track trends and adjust inventory levels dynamically.

5. Quality Control and Returns Management

a. Establish Quality Standards

Implement clear and strict quality control guidelines with your supplier to ensure that the slippers meet your standards. Defective products can lead to increased costs in the form of returns, refunds, and lost sales.

- Third-party inspections: Consider hiring someone to inspect your goods, especially if you have

large orders of slippers. Yes, you will pay to have someone look at your stuff before it comes to your place, but that can prevent you from selling defective items and save you a whole lot of money (and time) in the long run.

b. Negotiate Return Policies

Make sure and include in your conversations with your supplier your expectation for returns or replacements of slippers that do not meet your quality guidelines. Typically, if you buy a large quantity of slippers, a certain percentage can be deemed defective without giving you and your cash position a heartbreak.

c. Monitor Customer Feedback

Pay attention to customer feedback on the quality of the slippers. If multiple customers report issues, it may indicate a manufacturing problem that you need to address with the supplier. Tracking and responding to feedback quickly can help you manage returns and avoid further issues.

6. Supplier Relationship Management

a. Building Long-Term Relationships

Establishing a strong relationship with your supplier can lead to long-term cost savings. Reliable suppliers may be more willing to offer favorable pricing, prioritize your orders, or provide better payment terms.

b. Supplier Audits

Conduct regular audits of your suppliers to ensure they maintain high-quality standards, ethical practices, and efficiency in production. This can prevent costly disruptions and help maintain a steady supply of quality products.

- Sustainability and ethical practices: Consumers are increasingly concerned about the sustainability and ethics of the products they buy. Ensuring your suppliers adhere to ethical labor and environmental practices can improve your brand’s reputation and prevent costly scandals or boycotts.

7. Leverage Technology and Automation

a. Automated Ordering Systems

Automating the ordering process can reduce human error and streamline operations. This can include everything from placing orders to tracking inventory levels and monitoring supplier performance. Many businesses use EDI (Electronic Data Interchange) systems to streamline communication with suppliers, reducing administrative costs.

b. Data Analytics for Cost Reduction

Using data analytics to monitor your purchasing patterns, inventory levels, and supplier performance can reveal cost-saving opportunities. For instance, analyzing data could help you identify slow-moving inventory, allowing you to adjust order quantities and avoid excess stock.

c. Blockchain for Supply Chain Transparency

Implementing blockchain technology can improve supply chain transparency and reduce the risk of fraud, helping you verify the authenticity and quality of your slipper orders. Blockchain can also reduce administrative costs by automating processes like payment verification and contract management.

Conclusion

Managing costs in large-scale slipper orders requires a strategic approach that considers the entire supply chain—from negotiating prices with suppliers to optimizing shipping, inventory management, and quality control. By leveraging technology, building strong supplier relationships, and continuously analyzing cost drivers, you can reduce expenses and improve profitability. Careful planning and proactive management of these factors will ensure you make cost-effective purchasing decisions while maintaining product quality and meeting customer demand.

By following these strategies, even a novice buyer can navigate the complexities of large-scale slipper orders and manage costs effectively.