Managing supplier default risks in slipper purchasing is critical to maintaining a healthy supply chain and avoiding expensive disruptions. As a buyer, you need to understand these risks and how to mitigate them to save your company a lot of money and headaches. Supplier default risk is the risk that a supplier will not meet their contractual obligations. They might not meet their obligations because they go out of business, they have logistical challenges, or they have quality issues. In the slipper business, this risk can be amplified by things like seasonal demand shifts, relying on overseas suppliers, and fluctuations in raw

materials.

Here’s a comprehensive guide on managing supplier default risks in slipper purchasing.

1. Identify Supplier Risks Early

To effectively manage supplier default risks, you need to know what the key risk factors are in your supplier base. This means you need to evaluate your suppliers, both new and existing, on a few different fronts.

- Financial Health: Analyze the financial stability of your suppliers. This can include looking at their financial statements, their credit scores, and their payment history. If a supplier is in financial trouble, they are at a higher risk of defaulting.

- Geopolitical Risks: Slipper manufacturers are often located in countries that may experience political instability, changes in trade policy, or currency fluctuations. These factors can have a huge impact on a supplier’s ability to deliver.

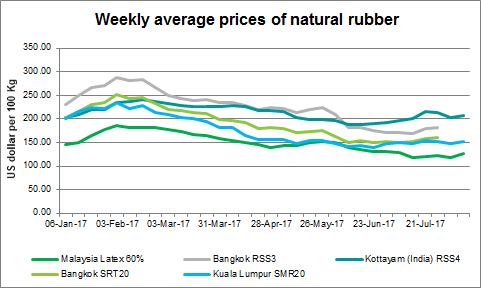

- Dependence on Key Raw Materials:In the slipper business, you might use materials like rubber, foam, textiles, or synthetic materials. These materials might be subject to price volatility or supply shortages. If your supplier is heavily dependent on certain raw materials, their risk of default goes up if those supplies are disrupted.

Actions

- Request financial audits or credit reports of key suppliers.

- Regularly monitor the political and economic situation in the countries where your suppliers operate.

- Understand your suppliers’ sources of raw materials and potential supply chain bottlenecks.

2. Diversify Your Supplier Base

Relying on a single supplier or too few suppliers increases your risk if one of them defaults. This is a common mistake people make when they’re trying to simplify their supplier management. But it puts your business at risk for supply disruptions.

Key Strategies

- Multi-sourcing: Work with more than one supplier for the same product or raw material. This reduces your reliance on any one supplier and gives you backup options if one of them defaults.

- Geographical Diversification:Spread your suppliers out across different regions. If there is political instability, a natural disaster, or a logistical disruption in one area, you can still get slippers from other regions.

Example

Let’s say you rely on a slipper manufacturer in China for most of your products. China is a big hub for slipper production. However, if something happens to disrupt your supply from China—like trade tariffs, port delays, or a pandemic—then you’re out of luck. By working with additional suppliers in other countries like Vietnam or Bangladesh, you can mitigate this risk.

3. Conduct Regular Supplier Audits

Supplier audits help you make sure your suppliers are doing what they said they would do and that they are maintaining their operational and financial standards. You should audit your suppliers both financially and operationally. This means you need to look at things like quality control, lead times, and capacity management.

What to Audit

- Financial Audits: Look at key financial ratios like debt levels and liquidity.

- Operational Audits: Check out production capacity, lead times, and inventory management systems.

- Quality Audits: Make sure the materials and finished products meet your standards. If the quality control is bad, it could be a sign the supplier is cutting corners because they’re in financial trouble.

Benefits

- Identify early warning signs of default.

- Build a stronger relationship with your supplier by getting involved in their operations.

- Understand potential capacity constraints that could impact their ability to deliver on time.

4. Contracts with Risk Mitigation Clauses

A strong contract is a key tool to mitigate supplier default risk. Your contracts should include provisions that protect you in the event of supplier default. You don’t want to be left holding the bag if your supplier doesn’t do what they’re supposed to do.

Essential Contract Clauses

- Force Majeure:Protects against unforeseen events like natural disasters, wars, or pandemics that prevent your supplier from doing what they’re supposed to do.

- Financial Health Reporting: Require updates on the financial health of your supplier. This could be quarterly financial statements or certifications from a third-party auditor.

- Penalties for Non-Performance: Include penalty clauses for late or non-delivery. This can compensate you for lost business or increased costs due to the supplier defaulting.

- Inventory Holding:In some cases, you might want to negotiate for your supplier to hold a safety stock of finished slippers or critical materials that can be quickly released in case of a disruption.

5. Monitor Market Conditions Regularly

Slipper purchasing, like many other retail categories, is affected by external market conditions. Price volatility in raw materials, changes in consumer demand, or global shipping disruptions can all impact a supplier’s ability to perform. Monitoring these external factors is a key part of proactive risk management.

Key Factors to Monitor

- Raw Material Prices: Slippers are made from rubber, foam, leather, or textiles. All of these materials can be subject to price volatility. If the price of rubber suddenly spikes, your supplier might be in financial trouble, which makes it harder for them to do what they’re supposed to do.

- Shipping Costs: Fluctuations in international shipping rates can also impact your supplier’s ability to deliver your slippers on time. If shipping costs go up, your supplier might be in financial trouble. They might cut corners, which affects the quality of your slippers or their ability to deliver on time.

- Regulatory Changes: Changes in trade policies, tariffs, or environmental regulations can impact your supplier’s operations. For example, if a country starts enforcing stricter environmental laws on rubber production, that could impact your supplier’s ability to get rubber.

Actions

- Subscribe to industry reports or market intelligence services that give you regular updates on raw material pricing trends and shipping rates.

- Keep in regular communication with your suppliers to find out how the market is affecting them.

6. Implement Contingency Planning

Even though you have things in place to prevent it, you need to have contingency plans in case your supplier goes out of business. That way, you can pivot quickly and keep from having a disruption in your supply chain.

Components of a Contingency Plan

- Back-up Suppliers: Maintain relationships with secondary or tertiary suppliers that you can turn to in case your primary supplier defaults.

- Safety Stock: Hold extra inventory of slippers, raw materials, or critical components to protect yourself from supply disruptions.

- Alternative Logistics Providers: If your supplier goes out of business because of a logistics issue, having a relationship with a third-party logistics provider can help you recover quickly.

- Financial Reserves: Make sure you have the financial flexibility to absorb the costs of transitioning to a new supplier or dealing with increased shipping or material costs if your supplier goes out of business.

7. Supplier Relationship Management (SRM)

Building strong, long-term relationships with your suppliers is one of the best ways to reduce your risk of a supplier default. When your supplier views you as a valuable partner, they’re more likely to tell you what’s going on and work with you to resolve issues before they become big problems.

Benefits of SRM

- Transparency: When you communicate regularly with your suppliers, they’re more likely to tell you if they’re having financial or operational difficulties.

- Collaboration: When you work closely with your suppliers on things like product development, lead time management, and quality improvement, you strengthen your relationship with them and make sure you’re on the same page.

- Negotiation Power: If you’ve been working with a supplier for a long time, you might have more leverage in negotiations. For example, you might be able to negotiate longer payment terms or priority fulfillment during peak seasons.

8. Use Credit Insurance

Credit insurance is an underutilized tool that can help protect your company from supplier defaults. This type of insurance covers your losses when your supplier doesn’t do what they’re supposed to do. It’s a financial safety net.

Advantages

- Financial Protection:If your supplier goes out of business because of bankruptcy or other financial issues, credit insurance can help you recover some or all of the money you lost.

- Improved Credit Terms: When you have insurance, it can give you the confidence to offer better credit terms to your suppliers. That can help improve your overall supply chain flexibility.

- Risk Diversification: When you buy insurance, you’re transferring some of the risk to the insurance provider. That way, you can focus on growing your business instead of worrying about whether your suppliers are going to go out of business.

Conclusion

Managing supplier default risks in your slipper business requires a proactive, multi-faceted approach. By identifying supplier risks early, diversifying your supplier base, conducting regular audits, and building strong contractual protections, you can significantly reduce your risk. Additionally, market monitoring, contingency planning, and credit insurance provide additional layers of protection to make sure your slipper supply chain stays strong even when you have a supplier default.