Foreward:As a buyer in the retail industry, you need to know the factors that impact the cost of manufacturing. Whether you’re new to purchasing or you’re looking for ways to improve your current buying process, understanding the factors that drive the cost of custom slipper manufacturing is vital for making good decisions. In this guide, we’ll discuss the key factors that drive the cost of custom slipper manufacturing and what you need to consider when you’re buying custom slippers from suppliers.

1. Material Costs

The material you choose is one of the biggest factors in the cost of manufacturing your custom slippers. Slippers can be made from a variety of different materials. Every material has a different price point, different durability, and different appeal to consumers.

a. Fabric Choices

- Cotton: Cotton is one of the most common materials for slippers due to its breathability and comfort. However, the cost of cotton can vary significantly based on quality, with organic cotton being more expensive than regular cotton.

- Synthetic Fibers: Materials like polyester and nylon are cheaper alternatives to cotton but offer different properties such as moisture resistance and durability.

- Wool and Fleece: These materials provide warmth and comfort, making them popular choices for winter slippers. Wool is generally more expensive than synthetic materials.

- Leather and Suede: These are high-end materials often used for premium slipper lines. While offering superior durability and a luxurious feel, leather and suede increase the overall manufacturing cost.

- EVA and Rubber: Slipper soles are commonly made from EVA foam, rubber, or other synthetic materials. The cost of these materials depends on factors like thickness, weight, and added features like anti-slip properties.

b. Sustainable Materials

If your customers are into eco-friendly products, you might want to source slippers made from recycled or biodegradable materials. But sustainable materials often cost more to produce because there’s not as

much supply, and they require special manufacturing processes.

2. Labor Costs

Where you manufacture your slippers is one of the biggest factors that determines your labor costs. There are certain countries that have lower labor costs, like China, India, and Vietnam. When it comes to footwear, including slippers, those are some of the biggest manufacturing hubs in the world. However, the quality of the product and the complexity of the product can also impact your labor costs.

a. Geographic Considerations

- Low-Cost Labor Markets: Manufacturing slippers in countries like China or Vietnam typically comes with lower labor costs but may also involve considerations regarding lead times and shipping.

- Higher-Cost Labor Markets: If you choose to manufacture in Europe or North America, expect higher labor costs, but you may benefit from shorter lead times and higher manufacturing standards.

b. Customization Complexity

The more customization your slippers need, the more your labor costs will go up. Simple designs with a limited number of embellishments are cheaper to produce. More intricate designs with embroidery, custom stitching, or hand-assembly are going to cost you more in labor.

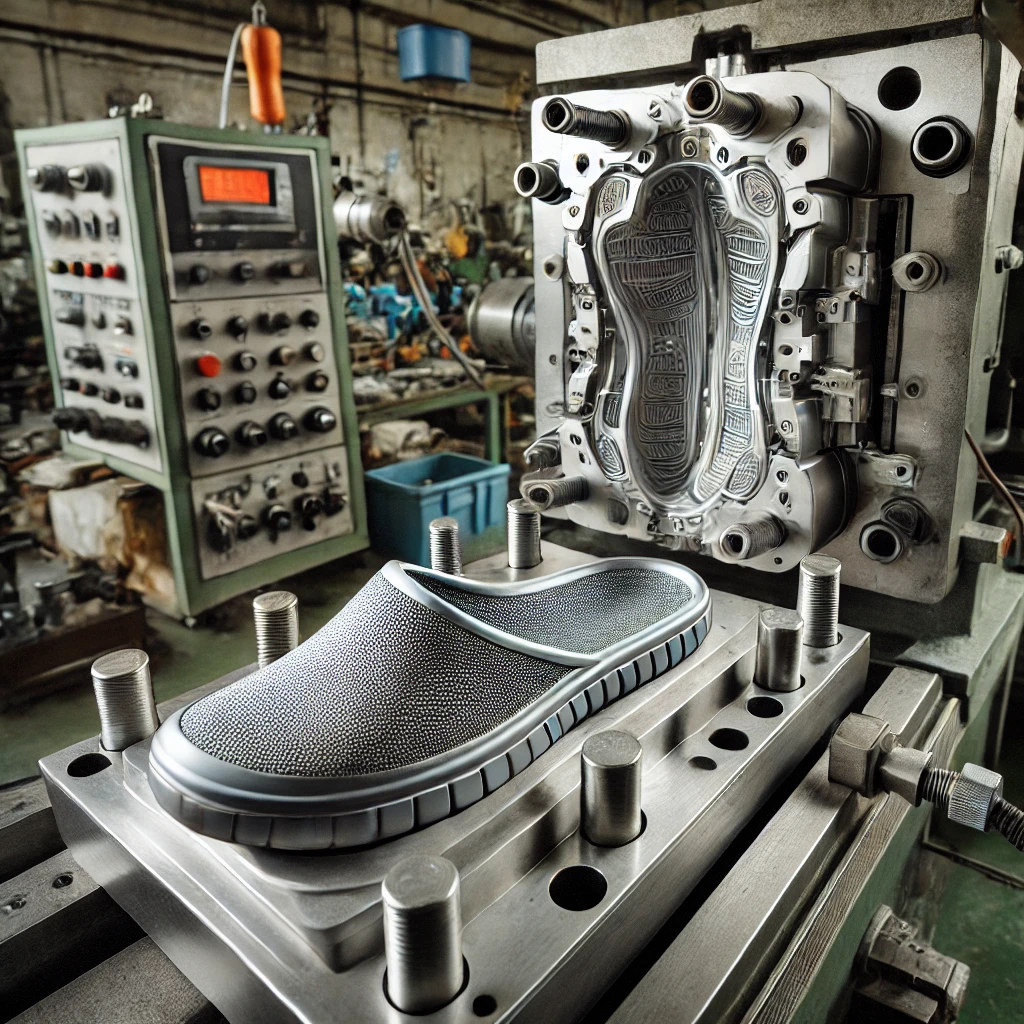

3. Tooling and Setup Costs

For custom slipper production, manufacturers need to create molds, dies, and templates to fit your specific design requirements. These are considered tooling costs and can be a one-time investment for large-scale orders.

- Mold Creation: For slippers with unique soles or custom shapes, molds need to be created. These molds can cost several hundred to thousands of dollars, depending on the complexity of the design.

- Die Cutting: For fabric or leather slippers, die-cutting machines may be required to cut materials into precise shapes, adding to the overall setup costs.

- Sample Production: Before mass production, a few samples may be required to ensure quality and design accuracy. Sample costs are often higher than the cost per unit for mass production but are crucial for quality control.

4. Minimum Order Quantities (MOQ)

MOQ is the minimum number of units a manufacturer will produce per order. Most manufacturers have a MOQ to make production economically viable.

- Small Batch Orders: For lower MOQ (e.g., 500-1000 units), the per-unit cost is usually higher because manufacturers need to account for the cost of setting up machines, molds, and labor for a relatively small production run.

- Large Orders: For higher MOQs (e.g., 10,000+ units), the per-unit cost decreases significantly as the fixed setup costs are spread across a larger number of units. Economies of scale play a crucial role here.

If you’re just starting out as a buyer and want to test a new product line, negotiating with manufacturers for smaller MOQs may be necessary. However, this will typically lead to higher costs per unit.

5. Customization Options

The more customization your slippers require, the more you can expect to pay for manufacturing costs.

a. Branding

- Logos: Adding a company logo can be done through embroidery, printing, or embossing. Embroidery is generally more expensive than printing but offers a more premium look.

- Labels and Tags: Custom labels and tags increase the perceived value of the product but also add to the cost.

- Packaging: Custom packaging, such as branded boxes or eco-friendly packaging options, adds additional costs but enhances the overall brand experience.

b. Design Features

- Patterns and Colors: Custom color schemes and patterns are another factor that can increase production costs. If the manufacturer needs to dye materials to match your brand’s color palette, this can lead to added expenses.

- Extra Features: Adding features such as memory foam insoles, fur lining, or arch support will increase the cost of the slippers but can also justify a higher retail price.

6. Quality Control and Certifications

If you’re going to sell these slippers under your private label, you’ll want to make sure they’re quality slippers. You want to make sure they feel good on your feet, look good, and don’t fall apart after two uses. Quality control measures and certifications may increase the cost of producing your slippers, but they’re necessary to protect your brand.

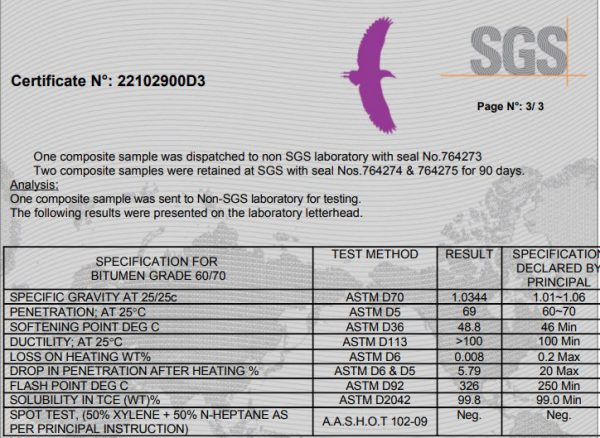

a. Inspection and Testing

- Factory Inspections: Hiring third-party inspection services to ensure factory conditions and quality control can cost extra but is often a worthwhile investment, particularly when dealing with large volumes.

- Material Testing: Testing materials for durability, safety (e.g., non-toxic materials), and performance (e.g., anti-slip properties) can increase costs but help meet industry standards and consumer expectations.

b. Certifications

- Eco-Certifications: If you are marketing eco-friendly slippers, certifications like Global Organic Textile Standard (GOTS) or OEKO-TEX will add to your costs but offer consumer trust.

- Safety Certifications: For children’s slippers or any product marketed as safe, additional certifications for child safety or compliance with national safety standards (e.g., European EN standards) may be required.

7. Shipping and Logistics

After production, shipping and logistics are a big part of your costs. Whether you’re importing your slippers from overseas or having them produced domestically, here are some logistics costs to consider:

a. Freight Costs

- Air Freight: Air freight is fast but significantly more expensive than sea freight. If you have tight deadlines or need to rush an order, air freight might be necessary, but it will substantially increase your costs.

- Sea Freight: Sea freight is a much more cost-effective option for larger shipments, though it comes with longer lead times. You’ll need to account for shipping times in your production schedule.

b. Tariffs and Duties

Depending on where they’re coming from and where they’re going to, you may have import duties, tariffs, and taxes that increase the landed cost of your slippers. Make sure you understand the taxes and the trade agreements between the countries involved so you don’t get surprised by additional costs.

c. Warehousing and Distribution

If you’re ordering a large quantity of slippers, you’re going to need to store them somewhere until you’re ready to distribute them to your stores. You need to think about warehousing costs and distributing them

to your individual stores or outlets when you’re putting together your budget.

8. Vendor Relationships and Negotiations

Building strong relationships with your suppliers can lead to cost savings over time. When working with a new manufacturer, establishing trust is key to securing favorable terms. As a first-time buyer, consider the following:

- Price Negotiation: Manufacturers are often open to negotiating prices, especially if you are committing to long-term contracts or bulk orders.

- Payment Terms: Negotiating favorable payment terms, such as extended payment periods or deposits, can help you manage cash flow more effectively.

- Long-term Partnerships: Committing to a long-term relationship with a manufacturer may allow you to negotiate better rates as they become more familiar with your business needs.

9. Cost Estimation Breakdown

To provide a clearer idea, here’s an example cost breakdown for custom slipper manufacturing:

| Cost Component | Estimated Cost |

|---|---|

| Material Costs | $1 – $10 per pair |

| Labor Costs | $0.5 – $1 per pair |

| Tooling and Setup Costs | $500 – $5000 (one-time) |

| Customization (e.g., logos) | $0.50 – $3 per pair |

| Quality Control | $0.20 – $1 per pair |

| Shipping and Logistics | $1 – $5 per pair (depending on volume and shipping method) |

| Tariffs and Duties | Varies by region |

Conclusion

The cost of manufacturing custom slippers is impacted by a lot of different things, including the material you choose, labor, how customized you want them, shipping, and how many you’re going to produce. As a buyer, you need to know these things so you can make good decisions and negotiate with your suppliers. You need to find the right balance between quality, customization, and cost to optimize your buying process.