Foreward:Supplier relationship management (SRM) is important to your business long-term, especially in industries like slippers where quality, cost, and timeliness are critical. It’s important to manage your suppliers effectively so you can keep your supply chain full and be competitive. This guide will show you the key strategies and best practices to manage your suppliers in the slipper industry.

1. Understanding the Slipper Supply Chain

Before we get into managing relationships, let’s quickly go over the slipper supply chain. Slippers, like most footwear products, have several stages from getting the raw materials to producing them, packaging them, and delivering them. Typically, your supply chain looks like this:

- Raw Material Suppliers: Providers of textiles, rubber, foam, or leather materials.

- Manufacturers: Factories that assemble the slippers, often located in regions like China, India, or Vietnam where labor costs are lower.

- Distributors and Wholesalers: Firms that facilitate bulk purchases and ensure product availability.

- Retailers: Your company, the final point in the supply chain.

By understanding these key players, you can better manage and segment your suppliers based on their role in the chain.

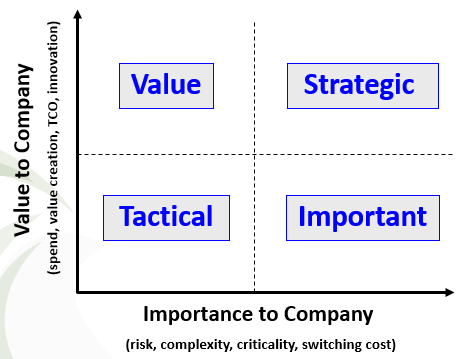

2. Segmenting Suppliers

Segmenting suppliers is an important part of your supplier relationship management (SRM). Not all suppliers are equal in the slipper industry. Some will be more important to your business than others. When you segment your suppliers, you can put your resources where they matter most.

- Strategic Suppliers: These are your primary manufacturers or material providers. They are critical to your production and should be managed closely.

- Tactical Suppliers: Typically, these are suppliers providing non-core materials or services that don’t directly impact product quality.

- Transactional Suppliers: These are less critical, offering generic or easily replaceable goods and services.

By categorizing suppliers based on their importance to your business, you can tailor your relationship management strategies to each group.

3. Building Strong Communication Channels

Strong communication is fundamental in managing supplier relationships, especially in a global industry like slippers where suppliers might be located in different time zones or regions. Good communication helps avoid misunderstandings, delays, and quality issues.

- Set Clear Expectations: From the outset, make sure that your suppliers understand your requirements in terms of quality, delivery timelines, and pricing.

- Regular Check-ins: Establish regular communication touchpoints. Monthly or quarterly calls can help you stay on top of potential issues.

- Use Technology: Tools like supply chain management software, collaboration platforms, and even email help you communicate better and keep things transparent.

Good communication builds trust, and trust is essential in any supplier relationship.

4. Ensuring Quality Control

In the slipper business, quality is essential. If you sell poor quality slippers, people will return them, you’ll lose sales, and it’ll hurt your supermarket’s reputation. That’s why you need to establish strong quality control mechanisms with your suppliers.

- Pre-Production Sampling: Before committing to large orders, ask suppliers for samples to check the quality. This helps in identifying any potential issues before full production.

- Third-Party Inspections: Hiring independent inspectors to check products at different production stages can ensure that the slippers meet your quality standards.

- Consistent Standards: Define your quality requirements clearly and make sure your suppliers adhere to them. Using standardized materials and processes across all suppliers helps maintain consistency.

Make it a point to audit your suppliers periodically, ensuring they are following the agreed-upon processes.

5. Negotiating Pricing and Payment Terms

Price is a big deal when you’re doing business with other businesses. In the slipper business, you need to make sure you can buy your slippers at a good price. You have to balance that with the quality of the materials and getting your slippers delivered on time.

- Benchmarking: Always benchmark the prices offered by your suppliers against industry standards to ensure competitiveness.

- Bulk Discounts: When possible, leverage your buying power by placing larger orders to negotiate better pricing terms.

- Flexible Payment Terms: Offering suppliers flexible payment terms can help both parties. For example, you might agree to longer payment periods in exchange for lower prices, which can benefit your cash flow.

Negotiating is about finding the balance between getting a good deal and maintaining a long-term relationship with your supplier.

6. Managing Risk and Contingency Planning

The slipper industry is like any other manufacturing industry. It has risks. Those risks include things like disruption to your supply chain, the price of raw materials going up and down, and political instability in different parts of the world. You have to manage those risks so you can keep your supply chain full.

- Diversify Suppliers: Don’t rely on a single supplier for critical components. Spread your risk by diversifying your supplier base across different regions and manufacturers.

- Develop Contingency Plans: Create contingency plans for supplier disruptions. Disruptions can happen for a variety of reasons, including natural disasters, economic instability, and shipping delays. Your contingency plan might include things like keeping higher inventory levels or having a backup supplier in place.

- Monitor Supplier Health: Keep track of your supplier’s financial stability and operational capacity. Suppliers who are struggling financially can become unreliable.

Proactively managing risk helps you keep your business running even when unexpected things happen.

7. Fostering Long-Term Relationships

While it’s important to negotiate the price you pay for your slippers, you don’t want to be the person who only cares about getting a good deal today. The best buyer-seller relationships are built on trust and a shared vision for the future.

- Incentivize Performance: Consider offering incentives like long-term contracts or performance bonuses for suppliers that consistently meet or exceed expectations.

- Collaborative Problem-Solving: You need to engage your suppliers as partners in your business, not just people who sell you stuff. When you treat them like partners, it encourages them to come to you with ideas and ways to improve your business.

- Sustainability and Ethical Sourcing: Today’s consumers care about how products are sourced. Work with your suppliers to ensure ethical labor practices and sustainable material sourcing. This can help strengthen your brand’s reputation while ensuring compliance with international standards.

Suppliers who think you’re going to do business with them for a long time are more likely to invest in delivering a higher quality product and better service.

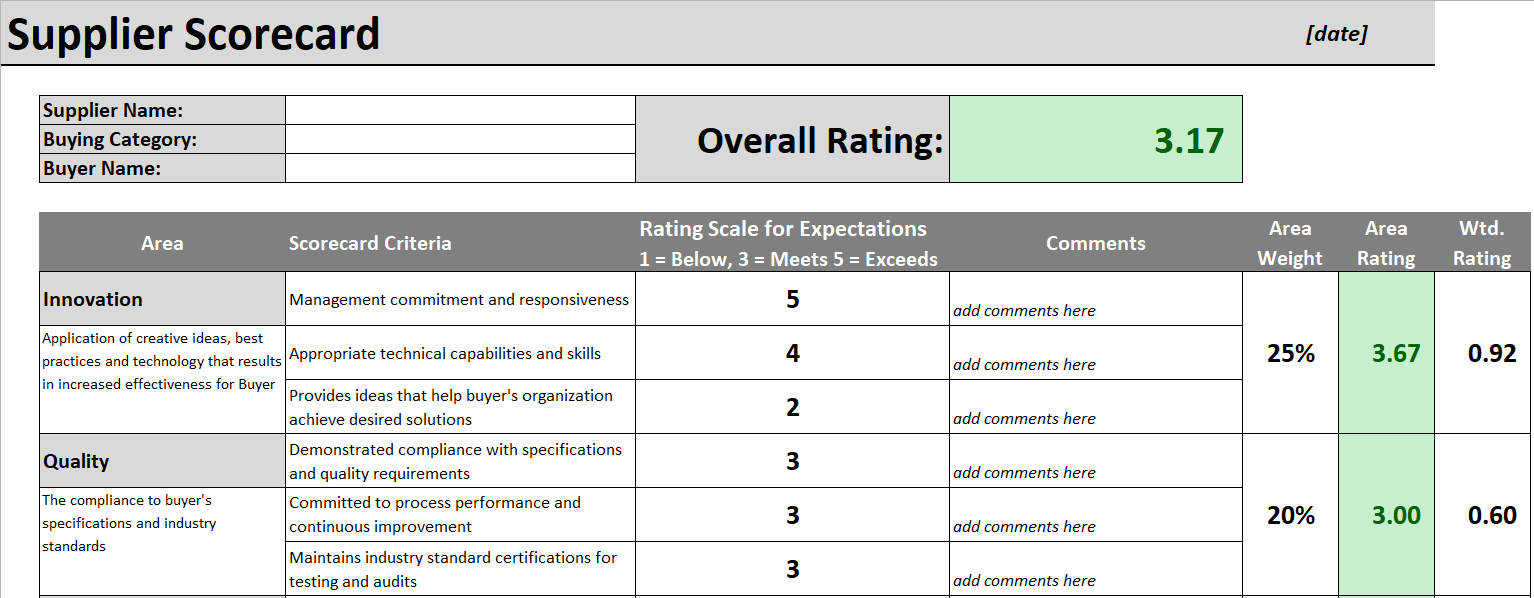

8. Supplier Performance Monitoring

You need to watch your suppliers to make sure they keep doing what you expect. That way, you’ll be able to maintain a good relationship with them. Key performance indicators (KPIs) can help you keep an eye on your suppliers.

- On-Time Delivery: Regularly monitor if your suppliers are meeting delivery deadlines. Delays can have a cascading effect on your operations.

- Defect Rates: Measure the percentage of defective products received. A high defect rate should trigger an investigation into the root causes.

- Cost Adherence: Ensure that suppliers are sticking to the agreed-upon pricing without unexpected cost increases.

One way to keep track of your suppliers is to use supplier scorecards. These scorecards are a way to measure how well your suppliers are doing. You can use them as a basis for your performance reviews with your suppliers.

9. Managing Disputes

Disputes are going to happen. They happen in every business, including yours. How you handle disputes can make or break your relationship with your supplier. Whether it’s a fight over price, delivery schedules, or the quality of your slippers, you need to handle it with care.

- Formalize Communication: When you have a dispute, you need to write it down. You need to document what the issue is and what you and your supplier are going to do about it. When you write it down, it helps you avoid misunderstandings.

- Mediation: If necessary, bring in a neutral third party to help mediate the dispute.

- Contract Review: Always refer back to the contract to ensure that both parties are aware of their obligations.

Dispute resolution is about finding a solution that works for both parties while maintaining a positive long-term relationship.

10. Leveraging Technology for Supplier Relationship Management

Technology can simplify many aspects of supplier relationship management, particularly in industries like slippers where supply chains are global and complex.

- Supply Chain Management Software: Platforms like SAP, Oracle, or specialized procurement software can automate many tasks, from tracking orders to monitoring performance.

- Digital Collaboration: Use digital tools to collaborate with suppliers in real time, especially for inventory management, forecasting, and demand planning.

- Data Analytics: Leverage analytics to gain insights into supplier performance, material costs, and market trends. This can help you make better purchasing decisions and strengthen your negotiation position.

By integrating technology into your SRM processes, you can increase efficiency and improve decision-making.

Conclusion

Managing supplier relationships in the slipper industry is a multifaceted process that requires careful planning, communication, and a strategic approach. By understanding the supply chain, segmenting your suppliers, focusing on quality control, negotiating effectively, and leveraging technology, you can build strong, mutually beneficial relationships with your suppliers. Doing so will not only ensure the consistent supply of high-quality slippers but also help you maintain a competitive edge in the market.

As a buyer, fostering long-term partnerships with your suppliers will enhance both your operational efficiency and your ability to respond to changing market conditions. By following these best practices, you’ll be well on your way to mastering supplier relationship management in the slipper industry.