Slippers are used in many industries, from hospitality and healthcare to personal use and retail markets. As a buyer in the B2B space, you may be responsible for sourcing slippers for your company, whether it’s for wholesale, hotel supplies, or private-label distribution. One of the most important steps in this process is the “slipper drawing,” which is the blueprint for what your final product will look like, how it’s structured, and how it functions.

In this guide, we’ll break down what slipper drawing is, why it’s important, and what you, as a B2B buyer, need to know when working with manufacturers.

What is Slipper Drawing?

Slipper drawing is the technical design of a slipper. It shows the dimensions, materials, shape, and structural components of the slipper. This drawing can be a hand-drawn sketch or a digital rendering using CAD (Computer-Aided Design) software. The slipper drawing is the blueprint for the manufacturing process. It’s important because it helps ensure the final product meets your quality, comfort, and aesthetic expectations.

In B2B transactions, the slipper drawing is often the first step in the procurement process. It allows you, the buyer, to see what you’re buying before you place a big order. A detailed and accurate slipper drawing helps prevent misunderstandings between you and the manufacturer. It also helps ensure you and the manufacturer are on the same page when it comes to the specifications of your product.

Why is Slipper Drawing Important in B2B Procurement?

Here’s why slipper drawings are important in the B2B world:

- Customization: Many buyers want custom slippers for their branding, which means they want specific designs, colors, logos, etc. A good slipper drawing helps the manufacturer understand what you want and how to make it.

- Accuracy and Consistency: Whether you’re buying 100 slippers or 100,000 slippers, you want them to be the same size, shape, and quality. The slipper drawing helps ensure each unit produced meets the specifications you’ve laid out.

- Cost Efficiency: The more detailed your drawing, the less likely there will be production errors that cost money in mass manufacturing. By working out the design during the drawing phase, you and the manufacturer can reduce the chances of defects in your final product.

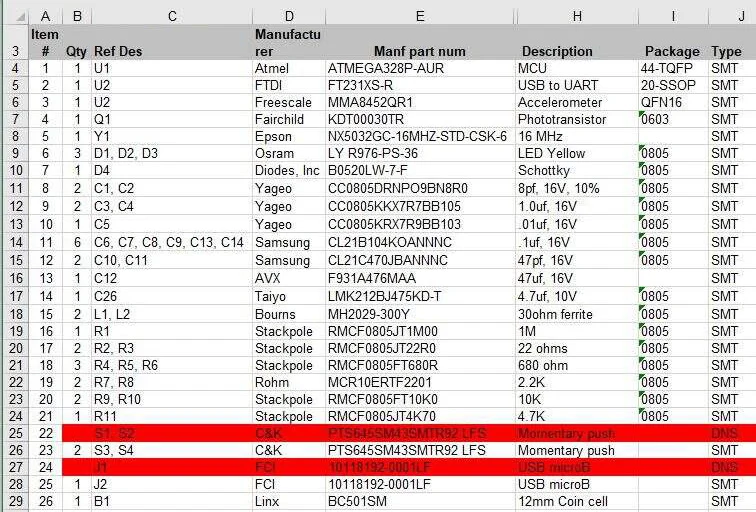

- Material and Component Selection: The slipper drawing includes a bill of materials (BOM). This is where you specify the fabrics, foams, and other materials you want to use. This is important because it helps you understand what’s going into your product, and it helps you make sure the quality matches the use you have in mind for your slippers.

- Regulation Compliance: Different countries and industries have different rules about what materials can be used and how things can be made. A good slipper drawing helps make sure your final product complies with the regulations in your country and industry. This helps you avoid legal and safety issues.

Key Elements of a Slipper Drawing

Here are some of the key components you’ll want to include in your slipper drawing to make sure it’s a good blueprint for manufacturing:

1. Shape and Size Specifications

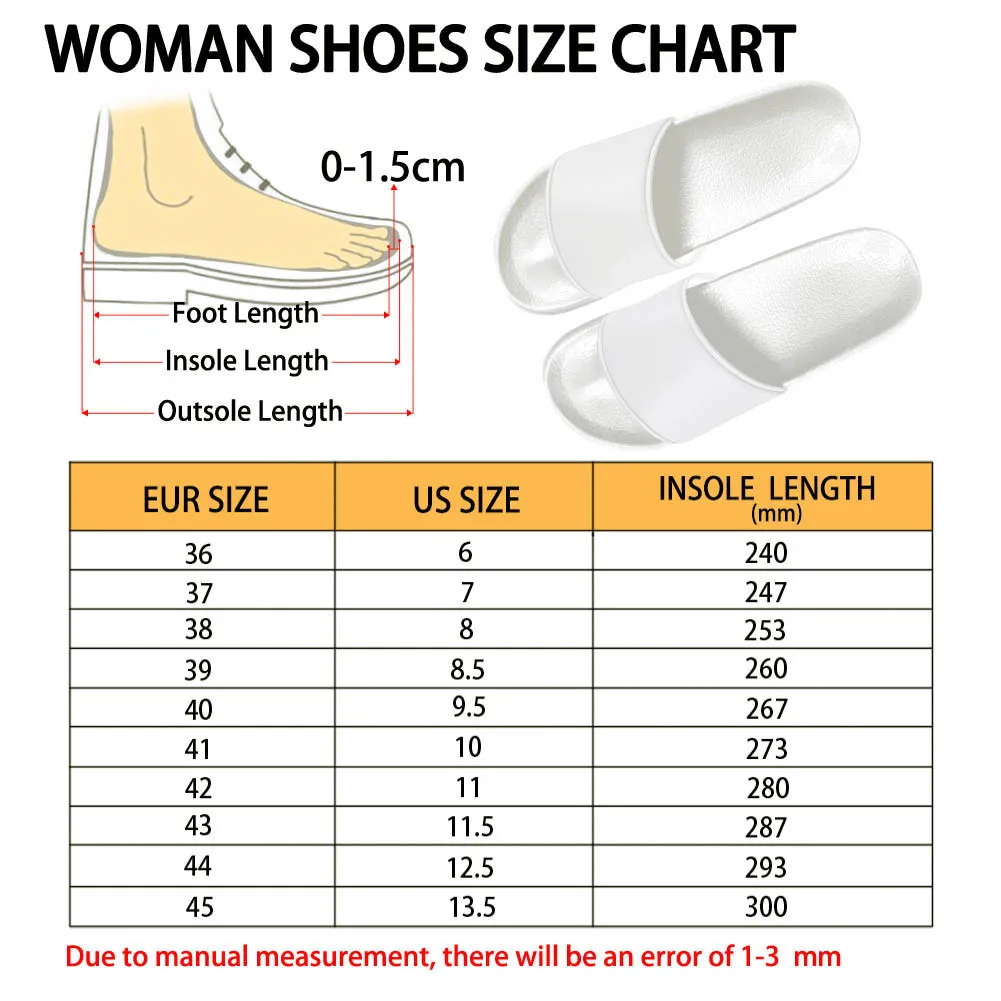

- Footbed Dimensions: The length and width of the footbed are important because you want your slippers to be comfortable. This is the part of the slipper that supports your foot, so you want it to be right. You may need different sizes depending on your target market.

- Heel and Sole Shape: Your slipper drawing should show how thick the sole and heel are. For example, slippers for hotels might have thin, lightweight soles. Orthopedic or healthcare slippers may have thicker soles with more cushioning.

2. Material Composition

Your slipper drawing should show what materials you want to use for each component.

- Upper Material: Some common materials include cotton, polyester, fleece, leather, and synthetic fabrics. Each material has different comfort, durability, and cost factors.

- Inner Lining: This is especially important for comfort. You might want your footbed to be terry cloth, memory foam, or some other soft material.

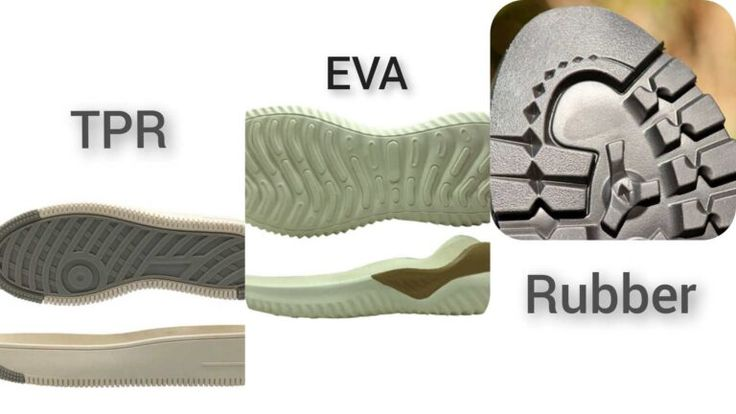

- Sole Material: Rubber, EVA (Ethylene Vinyl Acetate), TPR (Thermoplastic Rubber), and leather are common choices for the sole, depending on what you’re using your slippers for and where you’re using them.

3. Color and Finishing

You may want your slippers to be a specific color or colors to match your brand. Your slipper drawing should show the color or colors you want your slippers to be. You should also specify the color codes (like Pantone or CMYK values) so the manufacturer can get the color right. Also, if you want any special finishing details like embossing, stitching patterns, or your logo on your slippers, you should show those on your slipper drawing.

4. Additional Features

- Logo Placement: You may want your logo on the footbed, upper, or sole of your slippers. Your slipper drawing should show where you want your logo to go. You should also specify how you want your logo applied (e.g., embroidery, printing, embossing, etc.).

- Special Requirements: For example, slippers might need anti-slip stuff on the bottom, arch support, or water-resistant material. You want to show those things in your design.

Communicating with Manufacturers: What B2B Buyers Need to Know

When working with a slipper manufacturer, you need to communicate well so your slipper drawing turns into a great slipper. Here are some tips for working with a slipper manufacturer:

1. Discuss Customization Needs Early

If you need custom designs, sizes, or materials, tell them as soon as possible. The slipper drawing is the time to work that stuff out. They can adjust their process to accommodate you.

2. Request Prototypes Based on Drawings

Before you place a big order, ask for prototypes or samples based on yourvslipper drawing. This will let you see how the slipper looks, fits, and feelsvbefore you go into full production. It’s a lot cheaper and easier to make changes at the prototype stage than after you’ve gone into full production.

3. Clarify Technical Details

In B2B transactions, you can make expensive mistakes if you don’t communicate the technical details. Make sure your slipper drawing includes all the important stuff like how to sew it, what kind of material to use, and how dense the material should be. Ask them if they have any questions orneed clarification on any part of the drawing.

4. Use 3D rendering to help you see what the slipper will look like.

More advanced manufacturers may offer 3D renderings of your slipper design. This is especially helpful if you’re ordering high-end or highly customized slippers. It lets you see what the slipper will look like before you order it.

5. Control Lead Times

The manufacturer will give you a lead time based on how complicated your slipper drawing is and how many you’re ordering. Make sure you know how long it’s going to take and if there are any potential bottlenecks in the process.

Common Mistakes to Avoid in Your Slipper Drawing

As a B2B buyer, you need to be aware of the common mistakes that can happen during the slipper drawing phase.

1. Forgetting to tell them what material to use.

If you don’t tell them what material to use, they might use something else that you didn’t expect. This could affect the quality and durability of your slippers. Make sure you tell them what material to use for each part of the slipper.

2. Ignoring the rules and regulations.

Different markets have different safety and environmental standards. For example, if you’re selling slippers in the European Union, you might have to comply with REACH regulations (Registration, Evaluation, Authorisation, and Restriction of Chemicals). Make sure your slipper drawing follows the rules and regulations for the market where you’re selling your slippers.

3. Inaccurate Sizing

If you get the sizing wrong in your slipper drawing, you’ll have a bunch of returns or unhappy customers. Make sure your slipper drawing has the right sizes, especially if you’re ordering slippers for different markets (like Europe versus the United States). Make sure your sizes match the standard measurements for your target market.

Conclusion

For B2B buyers, the slipper drawing is an important part of the procurement process. It’s where you and the manufacturer get on the same page about what the slippers look like, what they’re made of, how big they are, and what branding elements you want on them. A good slipper drawing can save you time, prevent mistakes in production, and ensure you get a consistent, high-quality product for your business.

By understanding the key elements of the slipper drawing and working well with your manufacturer, you can make your slipper procurement process a lot better and easier.